PRODUCTS

NK SERVICE

DEALERS

NIVIUK

TESTIVALS & EVENTS

Back

GLIDERS

PARAMOTOR

HARNESSES

RUCKSACKS

SECURITY

EQUIPMENT & MERCHANDISING

SPARE PARTS & ACCESSORIES

Back

NIVIUK

OUR CREW

OUR FACTORY

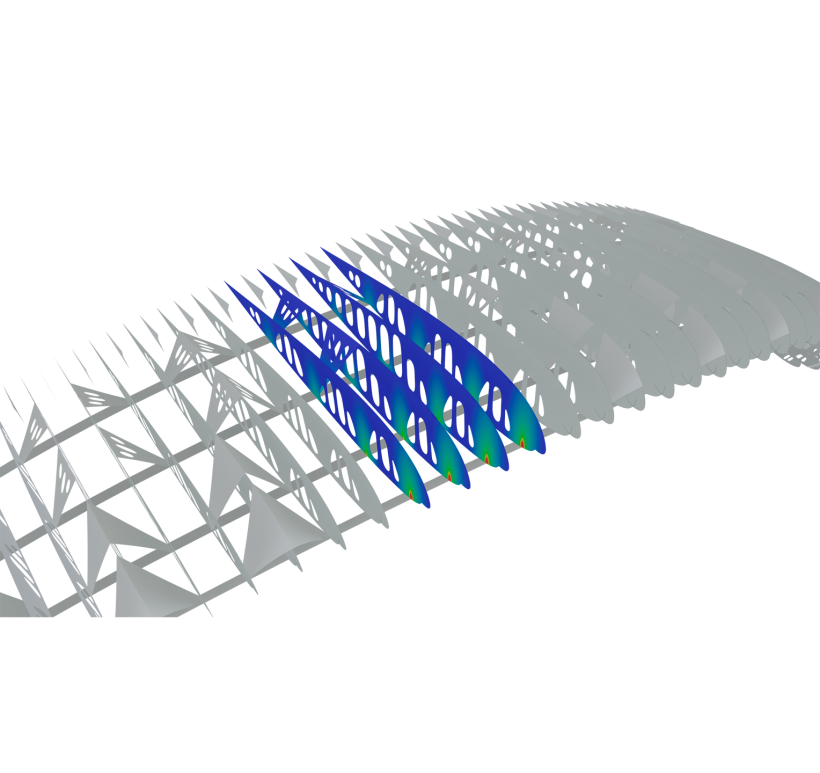

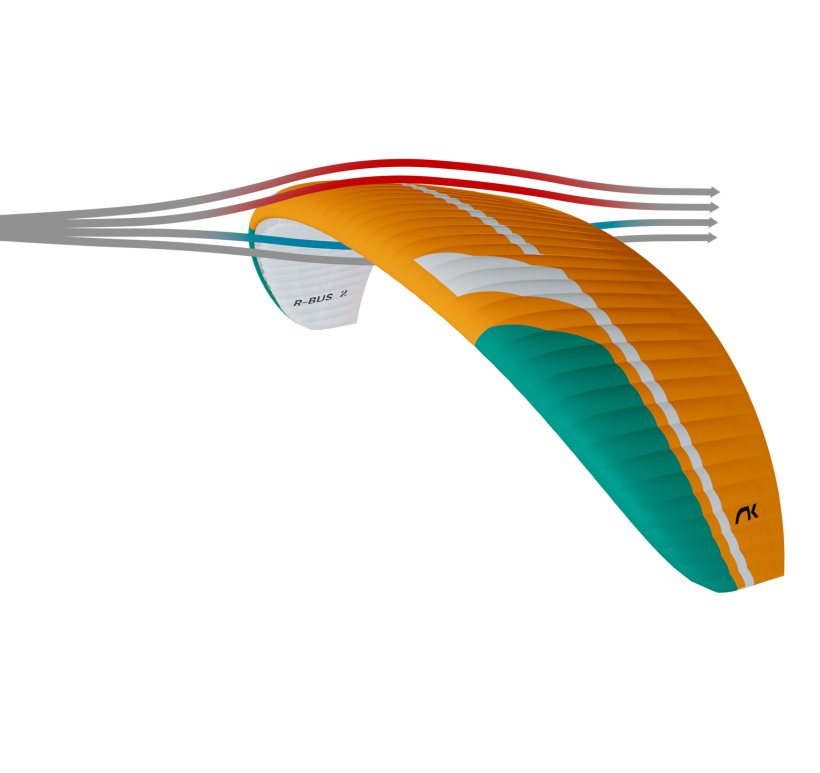

TECHNOLOGIES

P SERIES

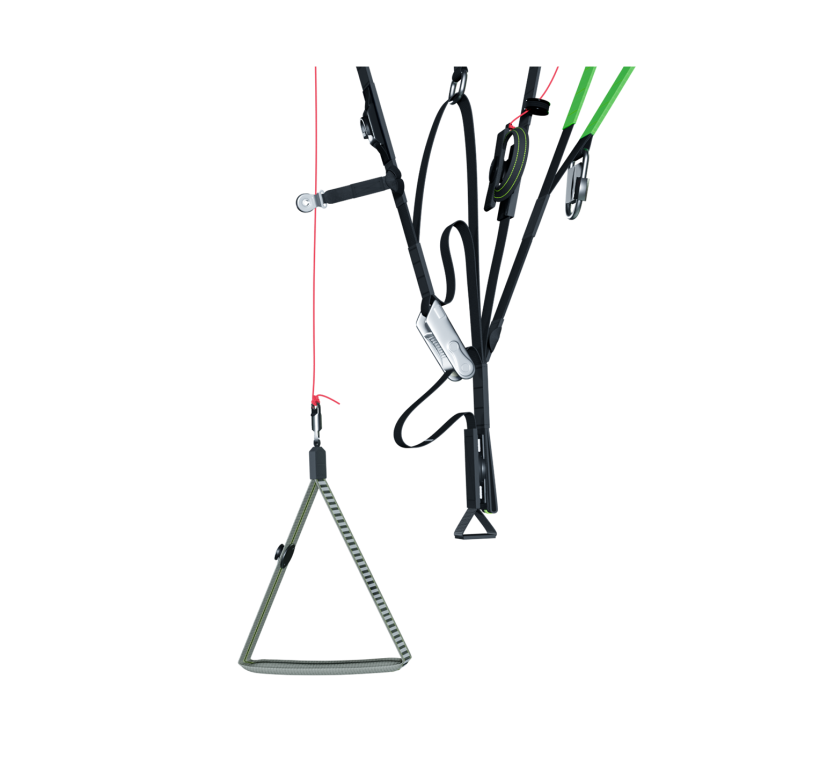

AERO SPEEDARMS TECH

FACTORY PILOTS

RACING PILOTS

ADVENTURE PILOTS

Back

Serial

KARGO 130

KARGO 160

KARGO 180

KARGO 220

KOLI BAG

KOLI PRO

KARGO URBAN

TRAVEL BAG

NKARE BAG

ZIPNKARE

INNER BAG

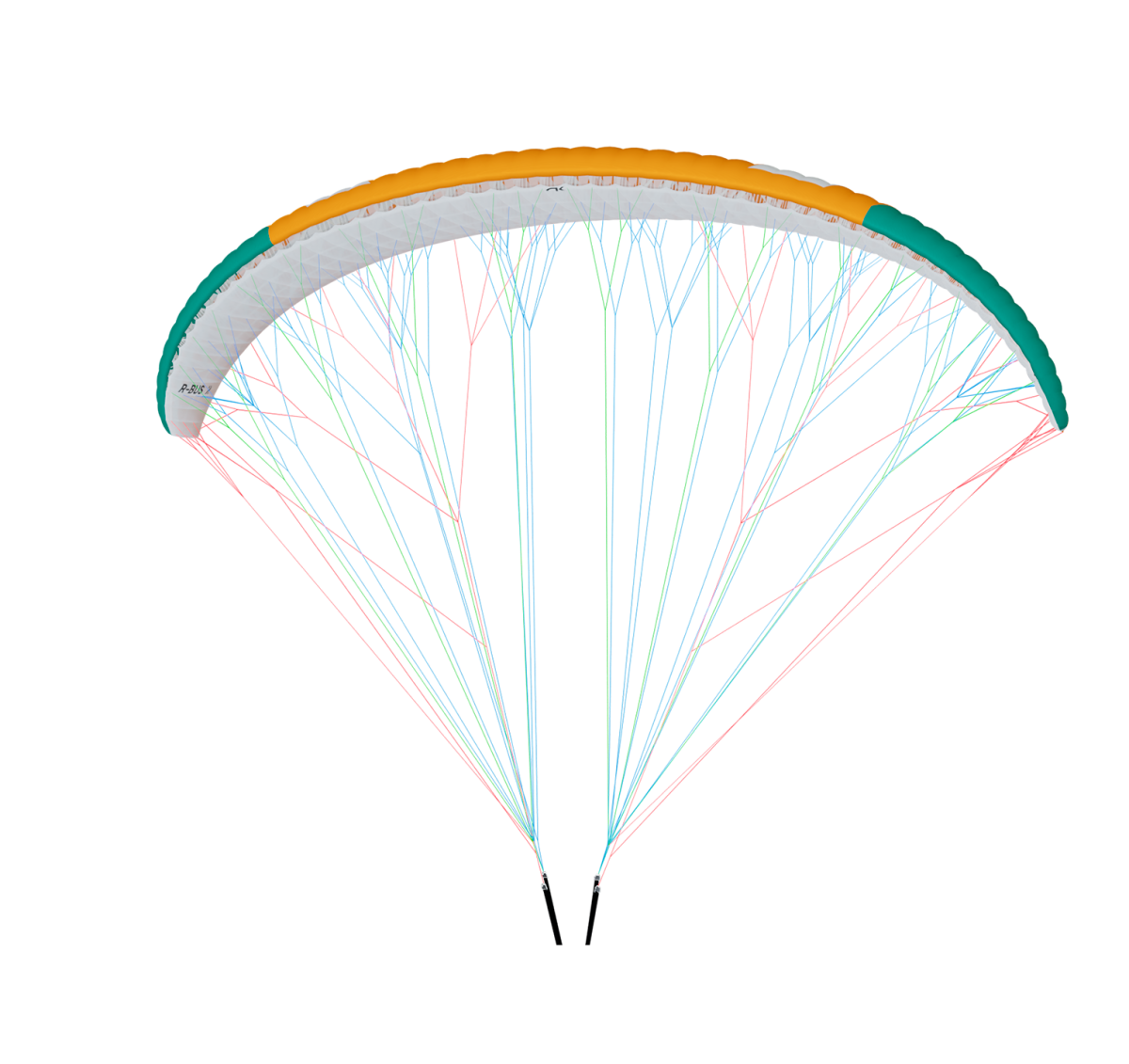

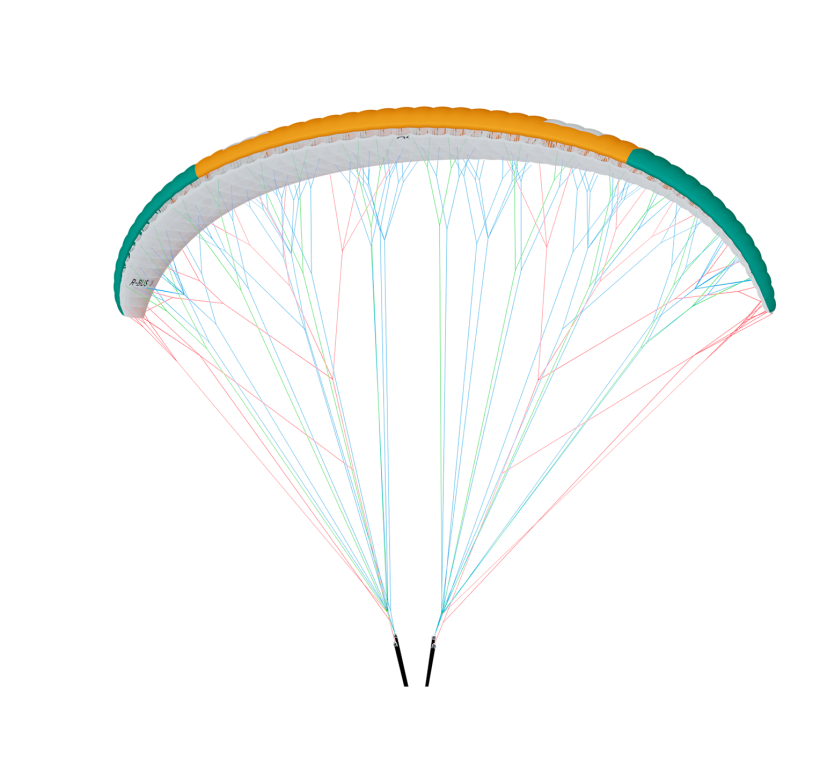

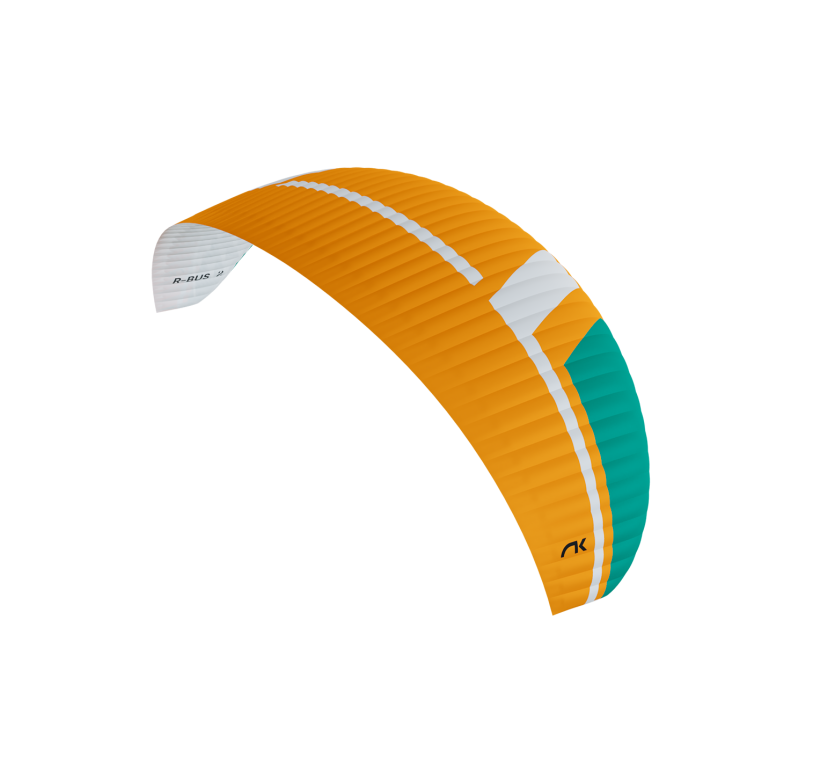

P Series